Other Processes

More Solutions. More Improvements.

Additional Ultrahigh-Pressure Process Solutions.

Ultrahigh-pressure waterjet solutions are used daily to solve some of the most challenging manufacturing processes, with high performance results.

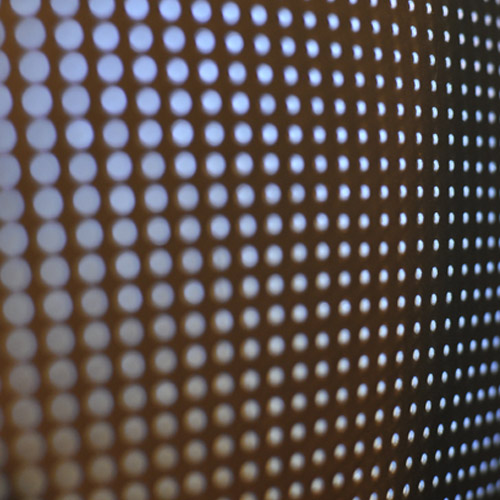

Waterjet Drilling for Turbine Components Machining

Drilling of various metals (titanium, superalloys and more) without any stress while delivering a very tight mesh of holes. Cut several thousands of holes with identical diameters in mass production.

Drilling diameter: 0.8 to 2.1 mm / 0.03” – 0.08”

Material thickness: 0.1 to 4.0 mm / 0.004” – 0.16”

- No thermal distortion (HAZ)

- No stress applied onto the part to be drilled

- No drilling-tool break, no cost of hard tools

- Very high accuracy and repeatability of the process

- Multiple drillings performed by waterjet

Our experience – drilling or micro drilling of many jet exhaust components for nacelle systems: Nozzles, Bifurcations, Tail ends, Acoustic components, etc.

Versatile Processing

Ultrahigh-pressure waterjet allows for a multitude of process solutions, inherent to its power and the way it responds to different materials. Have more questions about what waterjet can do? Contact our team to find out how waterjet can solve your advanced process challenges.

Our Team is Your Team

Our waterjet stripping experts understand what it’s like to perform waterjet stripping day in, and day out. We strip aerospace and nuclear parts for our customers every week in our In Advanced Production centers. Our process know-how and everyday operation allows us to partner with our customers in a unique way. Our lifetime support means you can rely on our partnership for years to come.

Meet Our Team

How can Aquarese help you?

Tell us more about your processing needs, and we’ll work with you to figure out the right solution.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.