High Pressure Deposition Cleaning

Safe, effective, smart deposition removal on wafer process chamber components

Ultrahigh-Pressure Waterjet Cleaning

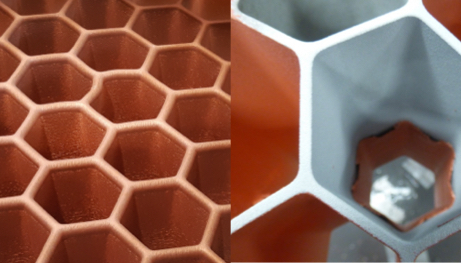

Our ultrahigh-pressure waterjet cleaning solutions remove deposits from process chambers regardless of the materials.

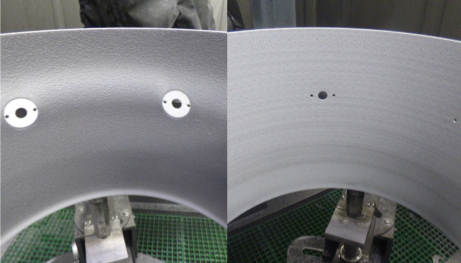

Using our high-pressure technology and cleaning process know-how, we find the fracture point of the deposit, so it can be peeled or fractured off without affecting the part.

Typical applications include: removing Tungsten from Aluminum shields, removing TiNAl from ceramic clamp rings, removing copper from stainless steel position rings.

Waterjet cleaning enables precision cleaning companies get rid of hazardous chemical cleaning and delivers the following:

• No base material removal, increasing parts’ lifetime

• Shorter processing time

• Collection of high-value deposits

• Removal of chemical & manual labor hazards

Surface Preservation

Deposits are removed by Liquid Force™, without damaging the base material.

Ergonomic System

Fully enclosed robotized waterjet system, designed for the Semicon cleaning requirements.

Eco-Friendly Process

No chemicals are used and no pollutants are released during the cleaning process.

Faster, More Cost Effective

Waterjet cleaning is up to 10x faster than chemical removal processes, saving time and money.

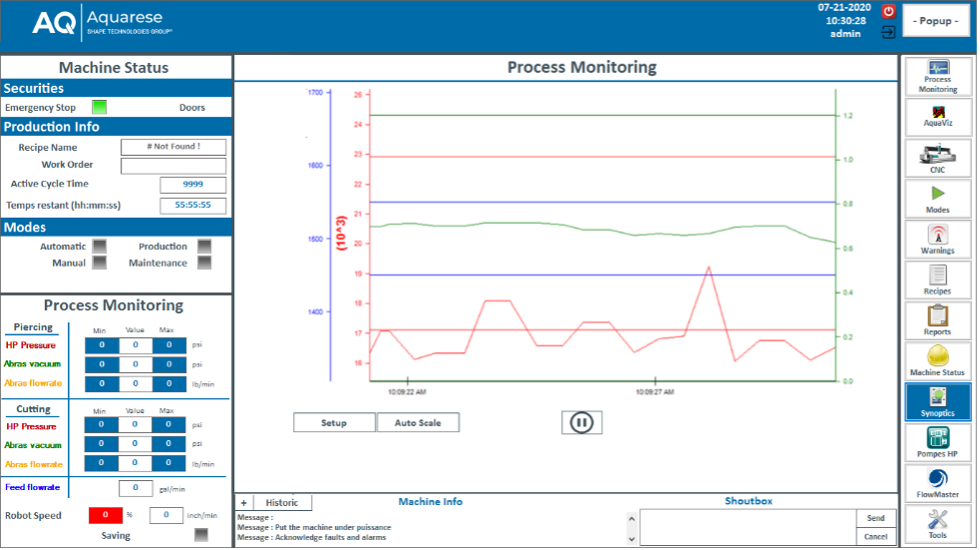

Advanced Process Monitoring

Our process monitoring ensures high performance throughout the entire production cycle.

We offer standard solutions or customized systems depending on your production needs.

25 Years in High-Pressure Stripping & Cleaning

Over 25 years, Aquarese has developed a large range of stripping solutions designed for various part dimensions and application. Our solutions are focused on process efficiency & sustainability.

.

How Does Ultrahigh-Pressure Waterjet Cleaning Compare?

[table id=3 /]

Our Team is Your Team

Our waterjet cleaning experts understand what it’s like to perform waterjet stripping day in, and day out. We strip aerospace and nuclear parts for our customers every week in our In Advanced Production centers. Our process know-how and everyday operation allows us to partner with our customers in a unique way. Our lifetime support means you can rely on our partnership for years to come.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.