Waterjet Stripping

Safe, Effective, Smart Coating Removal.

Ultrahigh-Pressure Waterjet Stripping

Our ultrahigh-pressure waterjet stripping solutions remove coatings with ease. Waterjet induces a shearing force onto the coating being stripped that is higher than the strength limit of the material. This in turn allows for efficient and safe removal of all types of materials.

Aquarese has developed the Aqualance™ – a highly reliable, extremely efficient rotary system with several jet options to ensure the right tool is available for your part. With 1500 hours before major maintenance interval the Aqualance has up to 5x the lifetime compared to competitive systems.

From removal of soft and hard deposits including thermal barrier coatings, to resins, adhesives, rubbers, and more, Aquarese stripping solutions remove tough coatings, fast.

Surface Preservation

Coatings are removed by Liquid Force™, without damaging the base material.

Eco-Friendly Process

No chemicals are used and no pollutants are released during the removal process.

Access Coatings in All Areas

Easily access even the hardest to access areas for coating removal.

Faster, More Cost Effective

Waterjet stripping is up to 10x faster than chemical removal processes, saving time and money.

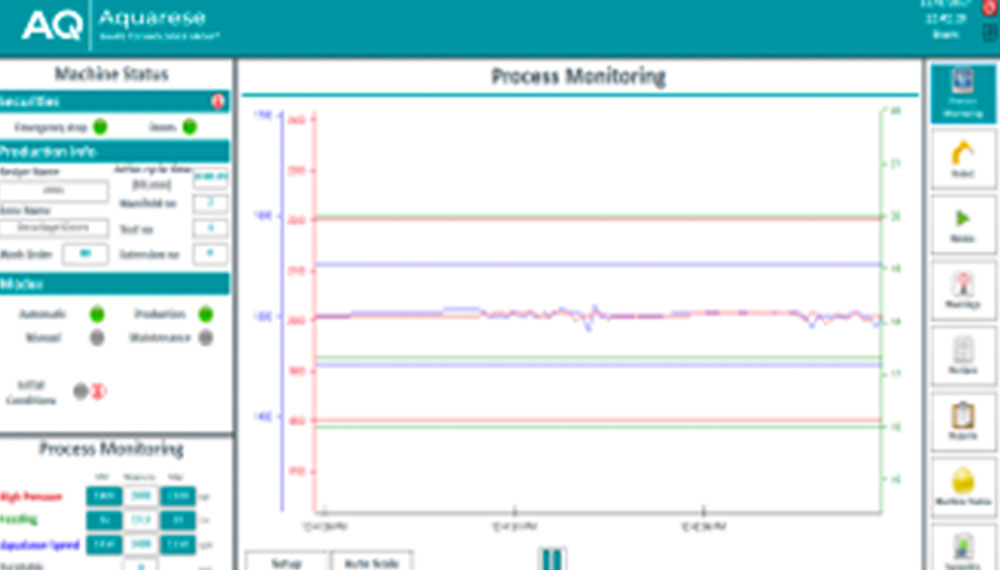

Advanced Monitoring Throughout the Entire Process

Our process monitoring ensures high performance throughout the entire process.

We offer standard solutions or customized systems depending on your production needs.

NADCAP Ready

Our waterjet stripping solutions are NADCAP ready and adhere to strict process requirements. Your part integrity is assured and part traceability is full managed and preserved. Our solutions come complete with automated production reports and data storage to fully manage part processing.

When is Waterjet Stripping Right for You?

How Does Ultrahigh-Pressure Waterjet Stripping Compare?

Stripping for MRO Aero Engines & IGT

Objective: Waterjet stripping is heavily adopted by OEMs and is an approved process in engine repair manuals for removal of thermal spray coatings for aero-engine (commercial & military) as well as industrial gas turbines.

Use cases:

- MRO (maintenance repair & overhaul): after a given number of cycles (take-off and landing), turbines are fully dismantled and each coated component is stripped to undergo inspection, repair & recoating.

- Rework: when an OEM (Original Equipment Manufacturer) sprays coating on a part and a fault is detected, the part is stripped and the coating can be applied again.

Benefits:

- Versatility: waterjet stripping removes all types of coatings from various base materials.

- Efficiency: much higher removal rate compared to chemical and other methods.

- Improved part integrity & increased number of repair cycles: no chemical or thermal impact to the part, no removal of the base material (no stock-loss).

- Eco-friendly: no chemicals used, only pure water which is recycled in close-loop

Stripping for SemiCon

In semiconductor wafer fabrication many deposition methods are used ( PVD, CVD, Etch, Diffusion, Ion Implant, and others) and during this operation chamber components build up the deposited material which requires cleaning for refurbishment of the parts.

Waterjet Stripping is an effective alternate to chemical removal and offers the following benefits:

- Versatility: waterjet stripping removes all types of coatings from various base materials.

- Efficiency: much higher removal rate compared to chemical and other methods.

- Improved part integrity & increased number of repair cycles: no chemical or thermal impact to the part, no removal of the base material (no stock-loss).

- Eco-friendly: no chemicals used, only pure water which is recycled in close-loop.

Stripping for Forges

Forges apply coatings to parts that act as solid lubricants. Once the forging process is finished these coatings need to be removed.

Waterjet stripping is an effective alternate to chemicals that offers the following benefits:

- Versatility: waterjet stripping removes all types of coatings from various base materials.

- Efficiency: much higher removal rate compared to chemical and other methods.

- Improved part integrity & increased number of repair cycles: no chemical or thermal impact to the part, no removal of the base material (no stock-loss).

- Eco-friendly: no chemicals used, only pure water which is recycled in close-loop.

Our Team is Your Team

Our waterjet stripping experts understand what it’s like to perform waterjet stripping day in, and day out. We strip aerospace and nuclear parts for our customers every week in our In Advanced Production centers. Our process know-how and everyday operation allows us to partner with our customers in a unique way. Our lifetime support means you can rely on our partnership for years to come.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.