Ceramic Shell & Core Removal

The Right Way. The Waterjet Way.

Waterjet Blasting for Ceramic Shell & Core Removal

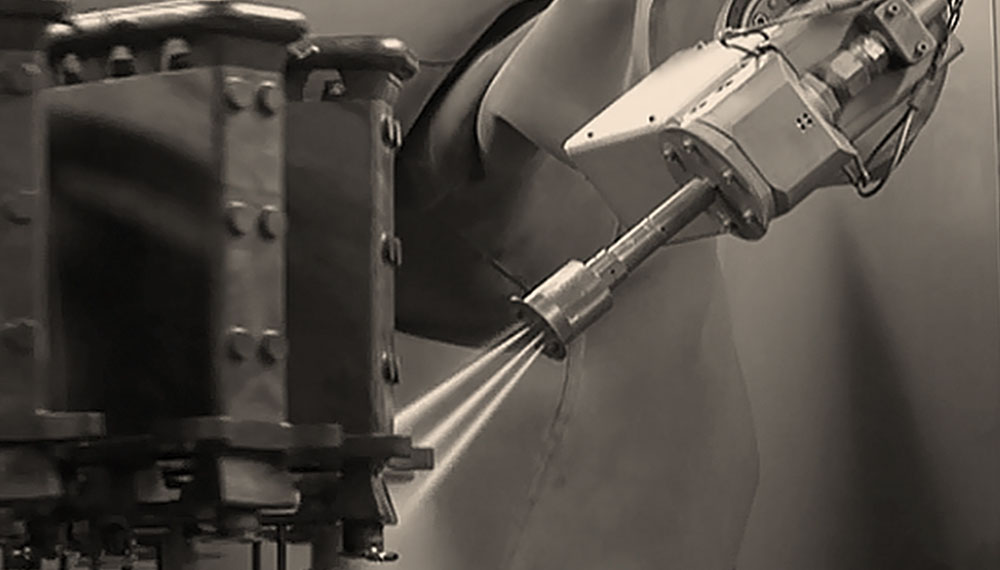

High pressure waterjet blasting is the ideal solution for ceramic shell and core removal on investment, lost wax, or plaster casting for any material. Waterjet provides a clean, safe, and repeatable process for aluminum, steel, titanium, and superalloys.

The Aquarese shell and core removal system is fully automated and removes 99% or more of the shell in a single operation – eliminating chemical leaching, manual waterblast, and bead blasting.

High pressure water can be tuned to perform shell knock-out and core removal in a single operation while preserving fragile features on thin walls or sharp edges leaving the base material undamaged. The result is a process that eliminates chemicals and toxic waste, while significantly improving your overall productivity.

Replaces Several Processes, with One

One single process removes both the shell and the core.

Eco-Friendly Process

Improves working conditions. No hazardous operations such as chemical leaching or manual cleaning. Reduced noise levels.

Preserves Part Geometry

Preserve delicate parts with thin walls and/or sharp edges

Highly Repeatable Performance

Optimal & proven process parameters with robotized waterjet. Consistent, quality performance.

Maximize Productivity & Efficiency

Our productive solutions require less manpower than traditional shell and core removal processes.

Aquarese offers several Core Shell Removal (CSR) models to accommodate for high-volume, high-mix, and extra-large castings.

We can solve cluster cut-off operations by combining CSR automation and our Waterjet Machining (WJM) system for a fully integrated solution with unmatched productivity, quality, and flexibility.

A single process to remove ceramic shells or cores from investment casting foundry using Automated High-Pressure Waterjet systems.

Shell removal for foundries

In the investment casting process, or lost-wax, a shell is created to provide a mold for the parts. After the molten metal is poured into the cast and the metal is solidified, the shell must be removed.

Automated High-Pressure Waterjet is a highly effective process that provides a safe, repeatable method to remove shell:

- Highly productivity: the automated system removes 99.9% or more of shell eliminating the need for chemical leaching and provides highly repeatable results.

- No damage to the part: does not bend thin walls or smoothen sharp edges.

- Improves operator safety: no hazardous manual operation, reduced noise level. Hands off the parts.

Core removal for foundries

As part of the investment casting shell process many inner cavities are filled with shell creating a core. Cores are difficult to remove and often require long & polluting chemical leaching process and/or hazardous manual operations.

Automated High-Pressure Waterjet is highly applicable to core removal and brings the following benefits:

- High productivity: with precisely directed rotating waterjet, eliminating or greatly reducing the need for chemical leaching.

- No damage to the part: does not alter the inner surface finish and geometry.

- Eco-friendly & safe for the operator: using pure waterjet (no chemical), removing manual operation and reducing noise level.

System Features

Hover over each circle to learn more about the system’s unique capabilities.

Smart Solution, Easy Operation

With a comprehensive and intuitive user-interface, our CSR solution offers simple, smart operation. You can setup up new parts quickly and process existing part programs with ease. Turnkey solutions feature automated loading/unloading with high accuracy positioning, and soundproof enclosures.

Our Team is Your Team

Our waterjet stripping experts understand what it’s like to perform waterjet stripping day in, and day out. We strip aerospace and nuclear parts for our customers every week in our In Advanced Production centers. Our process know-how and everyday operation allows us to partner with our customers in a unique way. Our lifetime support means you can rely on our partnership for years to come.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.