More Applications

The Versatility of Liquid Force™

One of the best attributes of waterjet is the ability to cut virtually any material, any shape, any thickness. From soft materials, cut using pure water only, to hard materials cut using abrasive waterjet, Liquid Force is the solution of choice for multiple applications and industries.

Waterjet for Food

The food industry typically requires products to be cut in various sizes or pieces. From production cutting to individual products, portioning food correctly while maintaining strict food safety requirements can be a challenge.

Waterjet is a cutting solution for food portioning that solves many of those standard challenges with ease. It’s an economical, reliable, and proven solution that has been used in the food industry for decades. Over the years, Aquarese has developed and installed several custom solutions adhering to even the most stringent specifications.

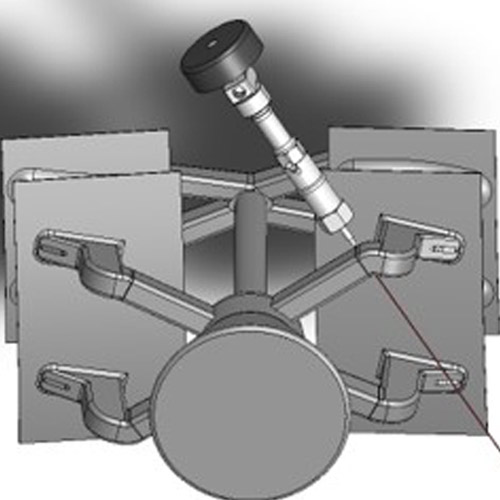

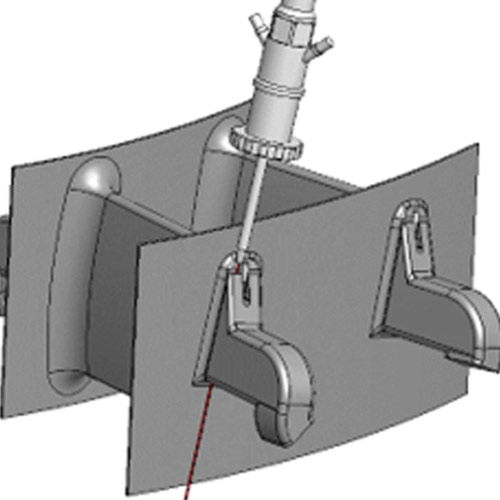

Waterjet for Medical Implants

Medical implants have undergone drastic innovation over the last few decades. Today, many implants are made of titanium, a material well suited for waterjet.

Whether the manufacturing process is machining or investment casting, waterjet can be used to rough the shape of the implant, to remove the gates of the cluster and/or to knock-out the ceramic shell. Aquarese waterjet cutting solutions and ceramic shell removal solutions can include automation to help with increasing volumes.

Waterjet for Automotive

The automotive industry requires highly-productive and cost-effective manufacturing solutions. For automotive interiors, such as carpets, headliners, dashboards, waterjet is the technology of choice. Light-weighting is a popular trend in the automotive industry and waterjet serves as an optimal solution for cutting several advanced materials in this space. Waterjet is also used to clean painting balancelles and to deburr powertrain parts such as diesel injectors. Last but not least, ultrahigh-pressure is used for autofrettage application of powertrain parts to increase lifetime.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.