Foundries

Improve Productivity in Foundries with Waterjet

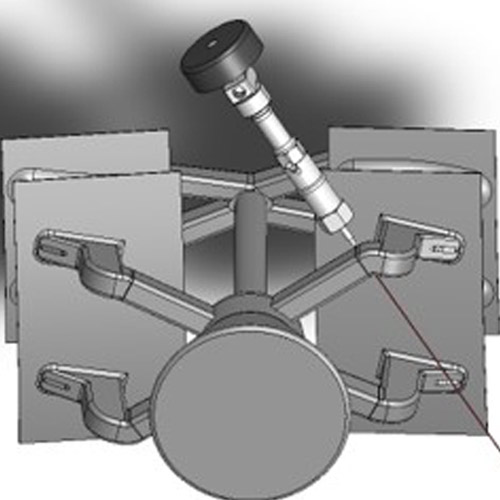

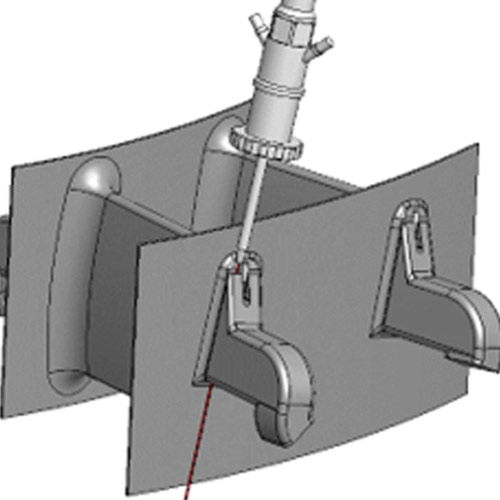

Investment casting is a popular process for making small, accurate castings. A ceramic shell is formed around a part made of wax. This wax is then melted creating a ceramic mold in which alloys is poured in. The removal of that ceramic shell and core after the casting process is complete has traditionally been a difficult and messy process.

Manual operations like hammering followed by shot blasting and chemical leaching drive up cost, and make for inefficient and unsafe conditions.

Waterjet Changed the Landscape

The introduction of waterjet significantly changed the productivity and efficiency of shell and core removal. Using the Aquarese CSR high pressure waterjet blasting system you can remove ceramic shell and core using ultrahigh-pressure water, for a faster more efficient solution.

Benefits of Ceramic Shell & Core Removal with Waterjet

Clean

Safe

Automated

Repeatable

How can Aquarese help you?

Tell us more about your processing needs, and we’ll work with you to figure out the right solution.

Aquarese is proud to be a Shape Technologies Group company, partnering with the world leaders in UHP technology to engineer and deliver the future of manufacturing process solutions.